Diamond-coated bits

Bits with bite.

Diamond-coated bits

One of the biggest problems with machine-driven screwdriving is that the tool often slips out of the screw head. This frequently results in damage to both the screw head and the tool. High follow-up costs can arise due to damaged surfaces and screw connections that can no longer be loosened. Diamond-coated bits help to mitigate the problem of slipping, making screwdriving more secure and economical.

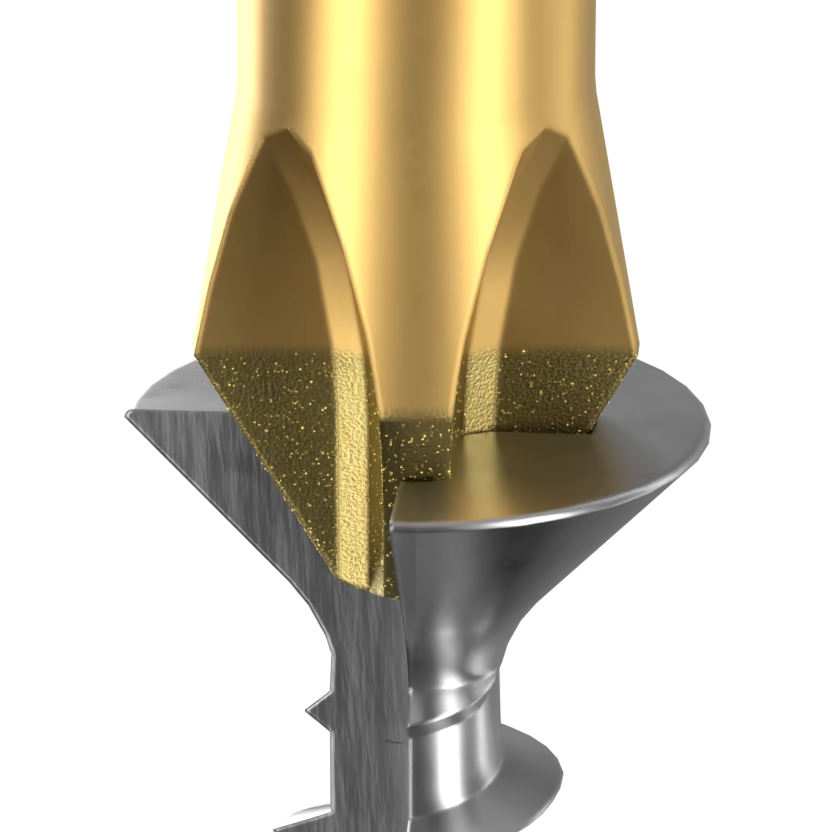

Bits with diamond coating

The diamond coating of the DC bits lowers the danger of slipping as the minute diamond particles literally “bite” themselves into the screw head.

Reduced cam-out forces

The minute diamond particles applied to the tip of the tool literally “bite” into the screw and ensure an exact, anti-slip fit in the head of the screw. This secure fit protects the screw. The cam-out forces which compel the user to apply greater pressure to the screw are considerably reduced.

Diamond coating

Wera Diamond Bits – for secure grip and precise work. The diamond coating prevents slipping, protects screws and reduces effort when fastening.

Diamond Bits Tools

Bit-Check 30 Diamond 1, 30 pieces

30 pieces

Bit-Check 7 Diamond 1 SB

867/1 BDC SB TORX® bits

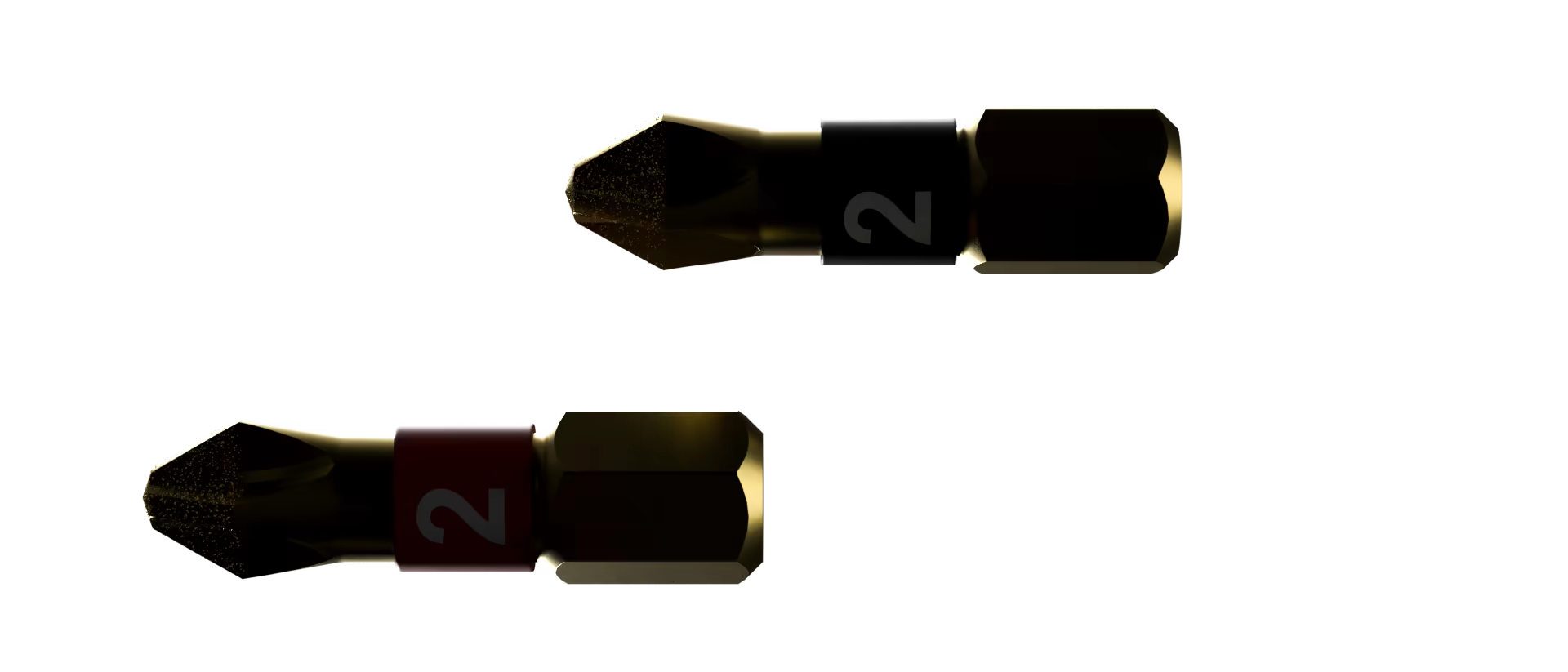

851/1 BDC bits

Bit-Check 12 Diamond 1, 12 pieces

12 pieces

855/1 BDC SB bits

851/1 BDC SB bits

851/4 BDC bits