Anyone can buy

We had a motorhome – a great one. It was chic, modern, spacious, and reliably showed us the most beautiful corners of Europe. It was our rolling home.

But there was this feeling, first subconscious, then increasingly pushing to the forefront. The feeling of wanting to own a completely individually designed "mobile home." It wouldn’t be the first crazy adventure we would take on, but it was already unusually demanding for us. No matter, it was born: "The One-Room Apartment Project."

But who are we really? We are four northerners: Wiebke, Knut, and our children Hannes and Rike. All of us are crazy about camping, infected by the travel bug, and sometimes a little quirky.

Start clear, we need a truck!

We reluctantly gave up our motorhome to a loving family just before the summer holidays of 2015. Immediately, we started looking for a suitable truck. Yes – we are older now, at least old enough that with our Class 3 driving license, we are allowed to drive up to 7.49 tons. The target size was set and also had to meet the following requirements: "it" should not be too old, preferably well insulated, not necessarily smell like a dead animal, and ideally already have a side door.

With butterflies in our stomachs and bumblebees in our backsides, we drove back home. Summer was over, the days were getting shorter, and the next planning phase, which we inserted due to many trade fair insights, fit well with the season. Dozens of ideas were discarded, reconsidered, new ideas were thought up or deemed unusable. Almost three months had passed, and still no "real" work had been done on the truck. We received the first skeptical head shakes: "Surely another whim of Wiebke and Knut... this will never work!"

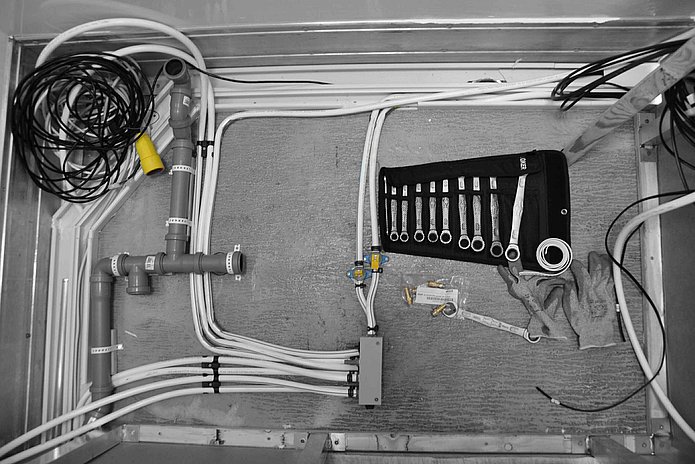

Even the biggest skeptics could not ignore the increasing delivery frequency per week. Several shipping companies delivered almost everything within three weeks that turns a motorhome into a rolling home. Interior, building materials, tools, electronic components, and more.

Let’s take stock as of March 2016: Interior walls refurbished, partitions and bed platform installed, heating 80% complete. The first furniture was needed. We had two go-to places that we visited frequently: One was a Swedish furniture store that sells furniture in a disassembled state. This was a big advantage for us due to necessary modifications. The other was our nearest hardware store, where we found laminated wood profiles and thin multiplex boards, providing a delicate, relatively lightweight yet stable construction base for the seating furniture.

Over 150 meters of cable have already been laid and are waiting for professional connection to batteries and control devices. The first windows have been installed, two seats placed inside, and the kitchen gives the impression that we will soon be able to heat up some ravioli.

„No project without obstacles“

Actually, everything had gone pretty smoothly so far. But there were also moments when things really caught up with us in a bad way. The worst experience so far was discovering that the GFK interior walls had osmotic damage in several places. This is a scenario more commonly known in boat building and required seven days of sanding, plus a week of filling, priming, and painting. Another shock was waking up the morning after professionally laying designer flooring, only to find the entire floor had detached.