Efficiency in Maintenance of Pumps

On a recent visit to a pump manufacturer, Wera's Solutions Specialist spoke to the engineers on the shop floor where it was clear that the innovations throughout the Wera range, could be of massive benefit to increase efficiencies both in the workshop and out on site.

The main issues the engineers face is around access and constantly coming across damaged, seized, or rounded fixings. As Wera are specialists in tools for this area, there are many products on offer that can help alleviate the problem.

Through the implementation of Wera tooling, fitting operations can be made much quicker and safer leading to a streamlined working environment. By speeding up these operations on site, downtime for the customer can also be greatly reduced, likely having significant financial implications.

Kompakt Kraftform 900

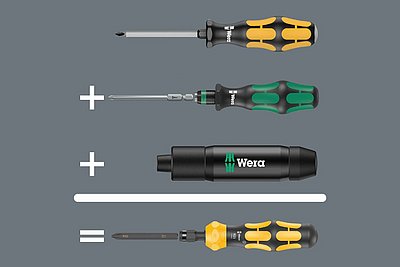

The Kraftform Kompakt 900 (or the KK900) is the ideal tool for the stripping down of motors and general pump assemblies. Typically, when they arrive at the workshop many fixings have seized, rusted and rounded heavily due to the conditions they have faced during service life. This can make strip downs frustrating and very time consuming.

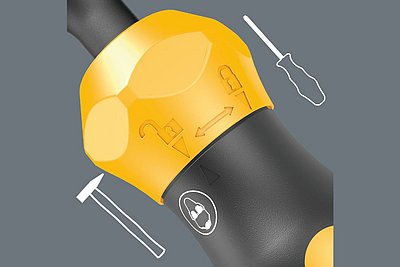

With the KK900, an impact wrench feature can be utilized to loosen seized screws by applying up to 25Nm of instantaneous torque. The tool handle can then be locked to disengage to cam unit in the head for use as an everyday interchangeable driver – combining the ergonomics of our Kraftform handle with the functionality of an impact driver.

Furthermore, no power is lost due to the pound through blade, which also improves the durability of the tool. This is complimented by the blades included in the set as they are made from a specific metallurgic blend to allow them to withstand the forces involved as the handle is struck with a hammer. They also undergo a specialised heat treatment process to give you the required hardness to re-cut the profile into the head of rounded off fixings for removal.

The handle features an interchangeable head for use with the 18 blades that come with the set covering Phillips, Pozi, Torx, Hex and Slotted profiles. A hex bolster on the handle can also be turned with a spanner for extra torque to be applied.

Implementation in the workshop will reduce the need for employees to look around for an impact driver or a tool with more leverage, due the functionality of the handle. It will also save time when stripping out stubborn fixings – whilst being a versatile everyday driver.